Q: What is a timer relay used for?

A: A timer relay is a device that opens or closes a circuit after a set amount of time. They are usually electromechanical and can be used in a variety of electrical systems and devices. Timer relays can be used for many purposes, including delaying the energizing or de-energizing of a circuit, controlling power outlets, activating lights, starting a motor, controlling an electrical load and so on.

Q: Where are timing relays used?

A: Timing relays are commonly used in a variety of industrial and commercial applications. Some common applications include machines, buildings, water segments, HVAC, and other applications. Some examples of their use include:

Flashing light control (time on, time off).

Engine auto start control.

Furnace safety purge control.

Motor soft-start delay control.

Conveyor belt sequence delay.

Q: How does an interval timer relay work?

A: Electromagnetism is the timer relay working principle. One relay coil is always on, while the other can be turned off and on with an electric signal sent through it from a control device such as a phone or computer system. The “on” coil receives power all the time, making it ready to activate at a moment's notice. When the control input is energized, the relay contacts immediately transfer. They will transfer back to their normal position at the end of the timing period. The control input must de-energize to reset the timer.

Q: What is a recycle timer relay?

A: A recycle timer relay, also known as a repeat cycle timer, duty cycling, or cycle timer, is a device that turns on and off at regular intervals. They conserve energy by turning a load off and on at regular intervals, and can offer precise feedback and event activation. Electronic timers trigger the pre-set time interval and transmit an output signal to the linked equipment to start pre-programmed events like alarms and on/off switching.

Q: What is the most commonly used timing relay?

A: Various types are available, but the most common, called “delay on make”, will energize the coil a set time period after power is applied to the relay. Similarly, a “delay on break” type holds the coil in for a time after the power is removed from the relay. Also, the industrial time delay relay is also one of the most common types used in manufacturing and other industrial applications. These devices are used to control the timing of conveyor belts, production lines, and other machinery.

Q: Why use a time delay relay?

A: There are various time delay relays, each with specific uses. Some common applications for time delay relays include controlling the start and stop of machines, controlling the on and off cycling of a load, and delaying the activation of a circuit. They are useful in implementing control logic with electronic control systems. Time delay relay helps to set delay time from a few seconds to even hours. Energy saving is possible.

Q: What is the difference between a timer relay and a relay?

A: Timing relays are similar to other relays in that they too use a coil to control the operation of contacts. The primary difference between a control relay and a timing relay is that the contacts of the timing relay delay changing their position when the coil is energized or de-energized. On a conventional Control Relay, the contacts are opened or closed when a voltage is applied and removed from the coil, however, for timer relays the contacts will open or close before or after an intentional time period.

Q: Can a relay be constantly on?

A: Yes, a relay can be constantly on. Many relays in industrial settings are continuously energized year-round, except during maintenance or emergency shutdowns. As long as you don't exceed the relay's voltage rating or voltage, it can be left on indefinitely. Keeping a relay constantly energized doesn't wear it out. However, keeping a relay in a constant on state can cause the coil to heat up and get damaged. This is unlikely, but will only happen if you have a low quality relay or apply excess current.

Q: Does a relay need a switch?

A: You are correct that a relay is basically just a switch, but it's a switch operated via remote control, so to speak. A regular switch controls electrical current by connecting or breaking the path of either the positive side of a circuit (most common) or the negative side of a circuit. A relay's internal mechanical switching mechanism (contacts) use an electromagnet (coil) to operate. When a relay contact is open, the coil is activated, which switches power on for a circuit.

Q: What are the three basic functions of a relay?

A: It is actually an "automatic switch" that uses a smaller current to control a larger current. Relay plays the role of automatic adjustment, safety protection, and conversion circuit in the circuit. A relay allows circuits to be switched by electrical equipment: for example, a timer circuit with a relay could switch power at a preset time. For many years relays were the standard method of controlling industrial electronic systems.

Q: What are the three major parts of a contactor or relay?

A: A contactor or relay will have a coil (to develop a magnetic field when energized), an armature (which is attracted by the electromagnetic coil when energized), and then contacts (which are attached to the armature, and close when the coil energizes).

Q: What is a time delay based relay operated load?

A: A time delay based relay is a relay that stays on for a certain period of time once activated. This circuit is made up of a simple adjustable timer circuit which controls the actual relay. The time is adjustable from 0 to few seconds but can be increased by increasing the time constant of the mono-stable 555-timer.

Q: How is a time relay wired?

A: Pin 30 is the power supply for a relay, and pin 86 acts as the switch for that pin. 85 is the grounding pin and 87 is the pin connected to a device. When the power is switched on through pin 86, the circuit is closed, and the power source is connected through pin 30. This current then powers the device connected to 87.J

Q: Can a time relay be used for both AC and DC applications?

A: Yes, a time relay can be used for both AC and DC applications. A relay is a switch that is electrically operated and is typically used to control a high-power or high-voltage circuit with a low-power signal. The relay contacts can switch AC or DC since they are completely isolated from the coil as long as the relay coil is driven to its specified voltage and waveform.

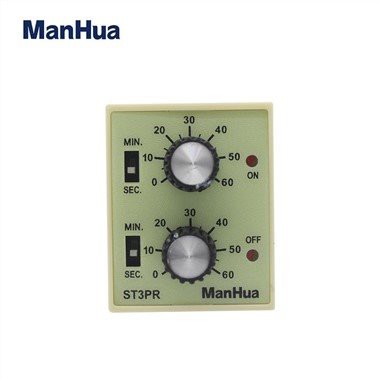

Q: Is it possible to adjust the time delay on a time relay?

A: Yes, you can adjust the time delay on a time delay relay (TDR). In many cases, you can adjust the delay time by turning a knob. You can also change the set time delay by modifying the time adjustment potentiometer. TDRs are a combination of an electromechanical output relay and a control circuit. The control circuit includes solid state components and timing circuits that control the relay's operation and timing range.

Q: What is the accuracy of a time relay?

A: Timer calibration can be used to define the length of a second, as seen by the timer. By lowering the timer calibration value, the timer can be accelerated. Since relay timers are derived from the system clock, it would stand to reason that relay timers maintain a 3% accuracy.

Q: What is the difference between a solid-state relay and a relay?

A: Solid-state relays normally have only one output contact, while electromechanical relays can multiple output contacts. A solid-state output has no moving parts and can last longer, but can only handle small loads. Relay outputs are relatively slow to switch states, whereas solid-state outputs are much faster to switch states. Relay outputs provide a physically-opened circuit, such that no voltage leak can occur across the open relay.

Q: What is the contact rating of a time relay?

A: Timer relay contacts are generally rated for 5 to 10amp resistive loads, and can often be supplied with solid state output contacts for lower level switching applications. Timing functions for timer relays include but are not limited to: on-delay, off-delay, and interval/one-shot modes.

Q: How do you test a time relay?

A: Check the contact status: Apply the rated voltage to the control coil to test the contact status. After a delay, check if the delay contact is closed (resistance is close to 0Ω) and disconnected (resistance is infinite).

Check the resistance: Use a digital multimeter (DMM) to test the resistance between each pole of the relay and the corresponding NC and NO contacts. All NC contacts should read 0 ohms to the corresponding pole, and all NO contacts should read infinite resistance.

Check the continuity: Use a multimeter to test the continuity of the contacts. A continuity test will confirm if the relay is closed or open.

Check the coil: Use a multimeter to test the resistance of the coil. A resistance test will confirm if the coil is burned out or not.

Check the click test: Run a couple wires from the battery to the control circuit pins 85 and 86. If the relay clicks, it's working. If it doesn't click, the relay is probably bad.

Q: What are the safety precautions that need to be taken while working with a time relay?

A: Use that exceeds the specification ranges such as the coil rating, contact rating and switching life should be absolutely avoided. Doing so may lead to abnormal heating, smoke, and fire. Never touch live parts when power is applied to the relay. Always disconnect power, use insulated tools, wear protective gear, follow wiring procedures, test for live circuits, use circuit breakers, and obtain proper training.